Company name: zhejiang huiren electronics co., LTD

Contact person: ms xu

Telephone: 0572-2207633

Phone: 18072606105

Email address: hrsales1@hzhuiren.com

Website: m.981682.cn

Address: 1818 gangnan road, economic and technological development zone, huzhou city, zhejiang province

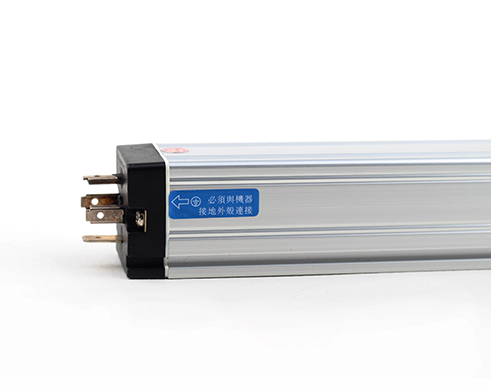

The linear displacement sensor of oil cylinder is usually magnetostrictive displacement sensor. Structure: the built-in oil cylinder displacement sensor adopts magnetostrictive principle, and the external structure is composed of electronic cabin, measuring rod (including waveguide wire), magnetic ring and power line. The internal structure is composed of electronic components and waveguide wires in the electronic cabin.

There are many output methods of displacement sensor, including analog output (0-10v, 4-20ma), digital output (RS485, 232, SSI), and bus output (canbus,profibus,modbus). Signal output can be selected according to various requirements. Generally speaking, the data line part of the output magnetostrictive displacement sensor with a suspended voltage (0-10v, 0-5v) cannot exceed 3 meters, and the signal may attenuate if it exceeds 3 meters.

After installing the magnetostrictive displacement sensor, the data pulsation is a common case for customers. The following is the analysis of the data pulsation.

First, connected to the PLC data jump and fluctuation is not large

Possible reasons:

1. Magnetostrictive displacement sensor (hereinafter referred to as displacement sensor) or the machine is ungrounded

2. Unstable supply voltage

Solutions:

Check whether the supply voltage is stable. If not, change the voltage and make the displacement sensor and the machine well grounded

Two, the data is fixed at a certain number

Possible reasons:

1. The sensor is burnt out due to incorrect wiring

2. Excessive supply voltage

Solutions:

Check whether the wiring mode is correct, check whether the power supply voltage is too large, and observe whether there is blackening outside the wiring of the electronic cabin of the displacement sensor. If you can't see the electronic cabin, you can smell whether there is a burnt smell to make a judgment.

Third, the data fluctuation, has the rule to jump

Possible reasons:

1. The displacement sensor itself is not well calibrated

2. Magnetic ring degaussing or magnetic components exist

3. The accuracy of displacement sensor is not enough

Solutions:

Recalibrate the displacement sensor and install the magnetic isolation element; Calibrate sensor accuracy to verify compliance.

Four, the data jump about randomly

Possible reasons:

1. There is interference source (such as large frequency converter, large motor)

2. There is something wrong with the circuit design of the sensor itself.

Solutions:

If this problem cannot be solved, it will be sent back to the manufacturer for maintenance and testing